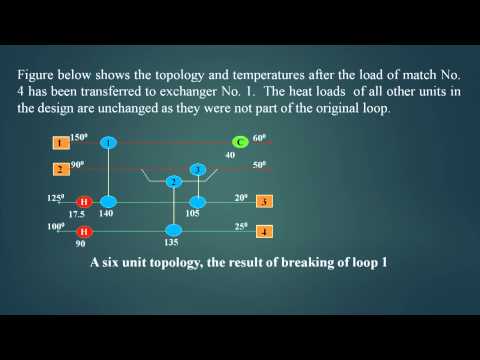

Welcome to the lecture series on process integration. This is module 5 lecture number 7. The topic of this lecture is optimization, specifically heat exchanger network optimization loops and paths. I have already mentioned the trade-off between the number of units and the consumption of hot and cold utilities in the previous lecture. We observed that as the number of pinch points increases, so does the number of heat exchangers in the heat exchanger network. This is due to the duplication of streams. As a result, when we opt for an AMI (Ameer) design, we usually end up with more heat exchangers. In the last problem, we found that we needed 12 heat exchangers for an AMI design, but when we considered a non-AMI design, the number dropped to 7. This indicated a potential for saving 5 heat exchangers by converting to a non-AMI design. So, what is the difference between an AMI and a non-AMI design? In an AMI design, we guarantee minimum hot and cold utility, while in a non-AMI design, we cannot guarantee this. As a result, the amount of hot and cold utility increases in a non-AMI design, leading to higher operating costs for the heat exchanger network. On the other hand, the non-AMI design reduces the fixed cost of the heat exchanger network by decreasing the number of units. Thus, there is a trade-off between the fixed cost and operating cost of the heat exchanger network. If converting to a non-AMI design leads to a decrease in the total cost, which is the TAC (Total Annualized Cost) of the end, then we should go for it. If not, it is not advisable. Hence, the conversion from AMI to non-AMI design depends on the profit obtained by reducing the TAC. Now let's discuss the scope of simplifying minimum utility...

Award-winning PDF software

Video instructions and help with filling out and completing Will Form 2220 Deductions